Remanufacturing process

The process at ACTRONICS is all about repairing, improving and reusing automotive components. Parts arrive with us and undergo a rigorous remanufacturing process that includes a full functionality test before being returned to the customer as new with a 2-year warranty.

1. Cleaning

Upon arrival, parts are cleaned and prepared for inspection. An assortment of blasting techniques and CNC machines are deployed to esnure that parts look like new and that the elctronic components are easily accessible and free from contamination for our staff.

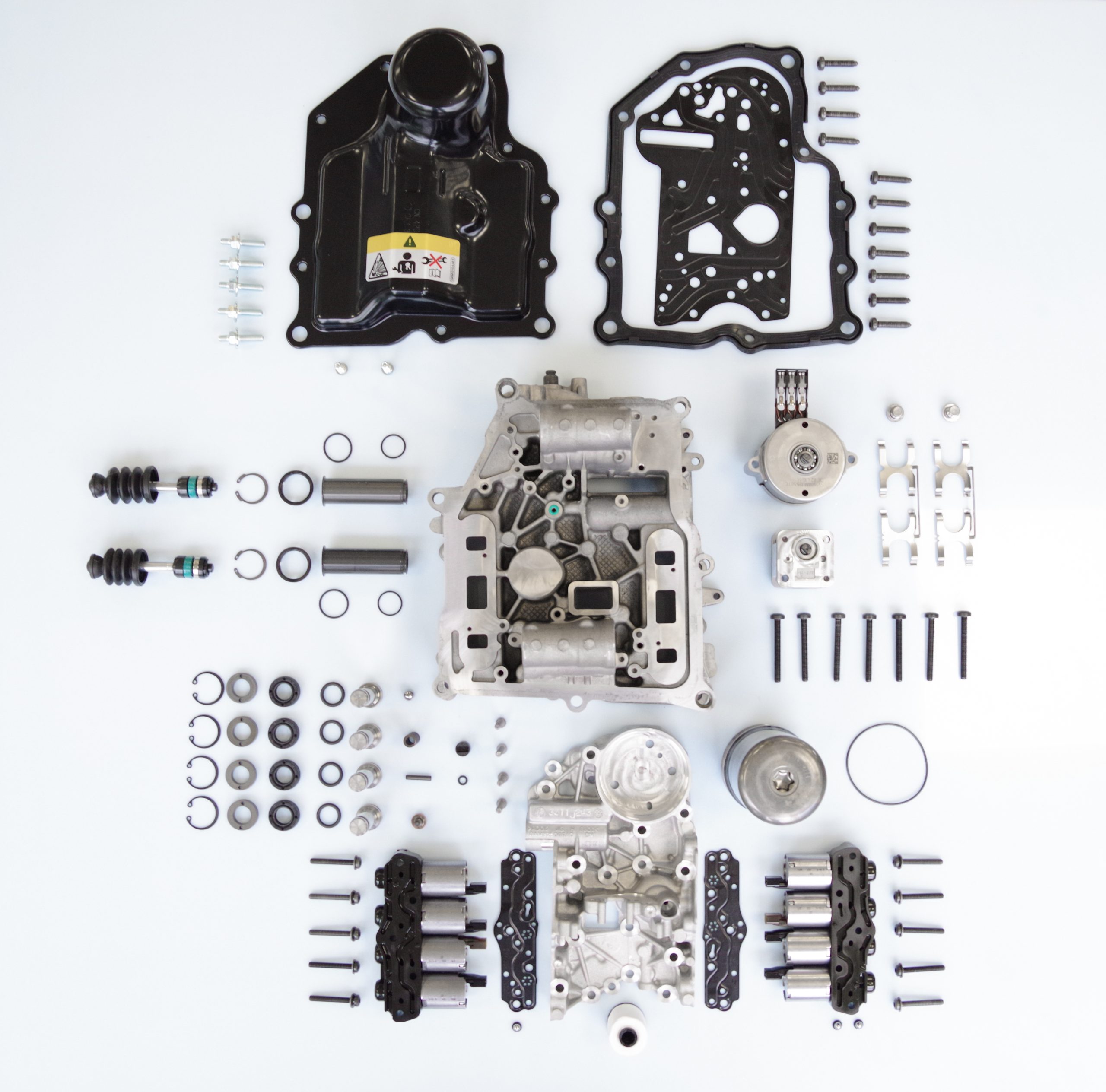

2. Inspection & Disassembly

Each part undergoes extensive diagnostics on our dedicated in-house testing rigs. If faults are found, we start the remanufacturing process immediately. If no faults are found, we provide the customer with a detailed testing report to support further diagnosis of the vehicle.

3. The Remanufacture

Faulty parts are fully remanufactured, during which weak or unreliable components are replaced to ensure a long service life. These processes give both us and our customers reassurance of long-term performance. In some cases, parts are not repairable, for example due to water damage, we can often replace them and transfer the original software in a service we refer to as a “plug and play” replacement.

4. Final Testing

Each remanufactured part is tested individually to meet our strict quality standards. After testing, the part is returned to the customer I recyclable packaging. We carry out regular spot checks using advanced X-ray machines, microscopes and inspection cameras to ensure quality.

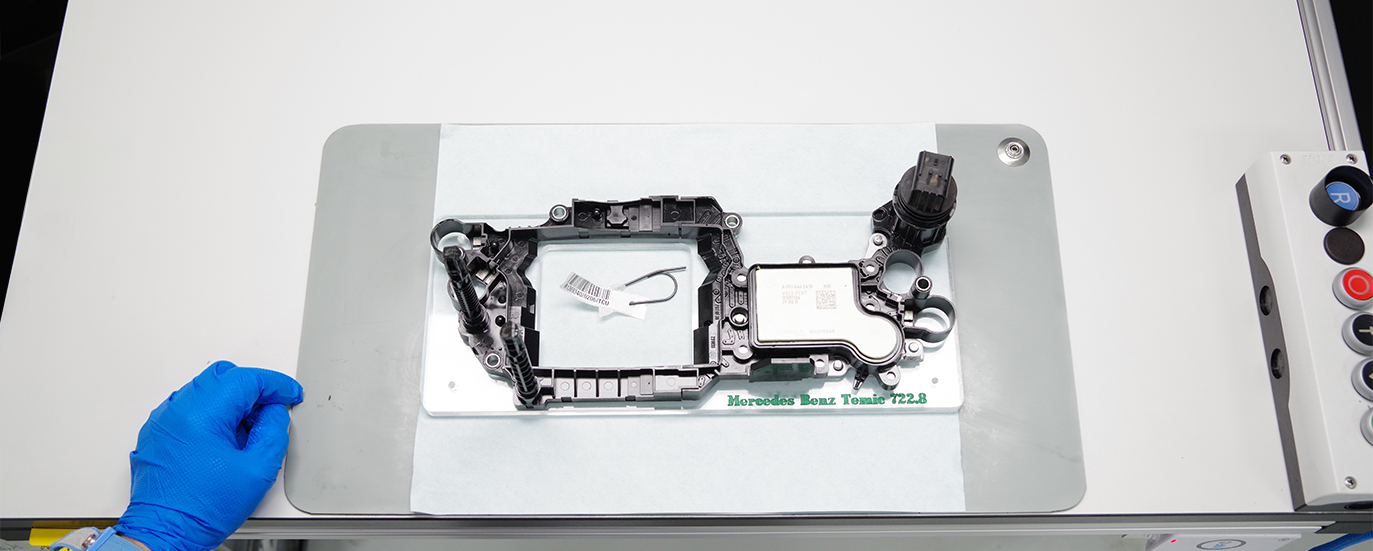

Automation where possible, expertise where necessary

Our remanufacturing process is either partially automated or manual depending on the component. We work with automated processes to improve efficiency and manually for complex tasks where human precision is required.

(Semi) Automated Remanufacturing

- Supports the sustainability of our industry

- Inline with strict protocol such as APQP, EFMEA and PPAP.

- Utilises Vapor Phase soldering and Pick & Place tooling for precise and reliable assembly

- Automated bench testing to ensure quality

Expert Remanufacturing

- Complex electronic systems addressed with specialist knowledge

- Each component undergoes extensive endurance testing

- A complete guided process from start to finish

- Verified using the 4-eyed principle for quality assurance

- X-Ray inspection of soldering for process optimisation and assurance